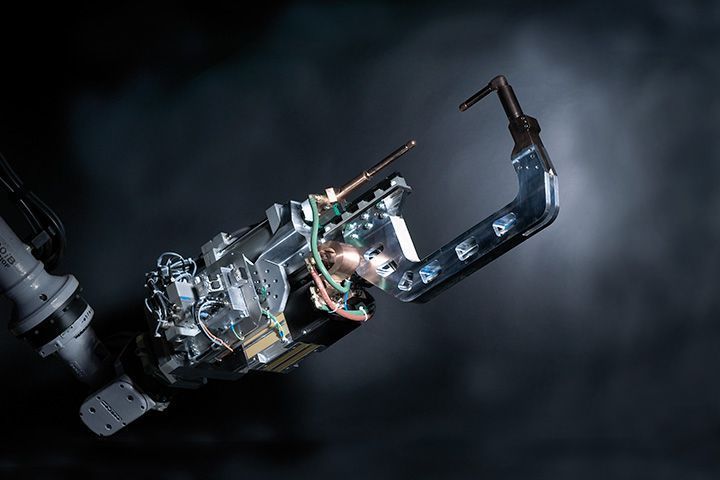

Full power for demanding aluminum welding: the powerGUN

With consideration of current developments in the automobile industry, the use of lightweight materials is continuously increasing. Associated with that are increased demands put on resistance welding: Because for aluminum welding, higher currents are required. And that is exactly what our innovative powerGUN robot welding gun achieves. Developed by our engineers in two version variants for different material thicknesses, it helps customers around the world with process-reliable aluminum spot welding in the highest perfection and speed.

Powerful features for more efficiency and productivity

The core components of our servomotor-driven powerGUN are high-power medium frequency welding transformers for up to 80 kA. They simultaneously guarantee high welding current and long duty cycles. Increased cooling ensures perfect heat dissipation and the bending of the gun arms on the torsion-free basic gun body was minimized. An integrated force measuring sensor monitors the required electrode force and force profile.

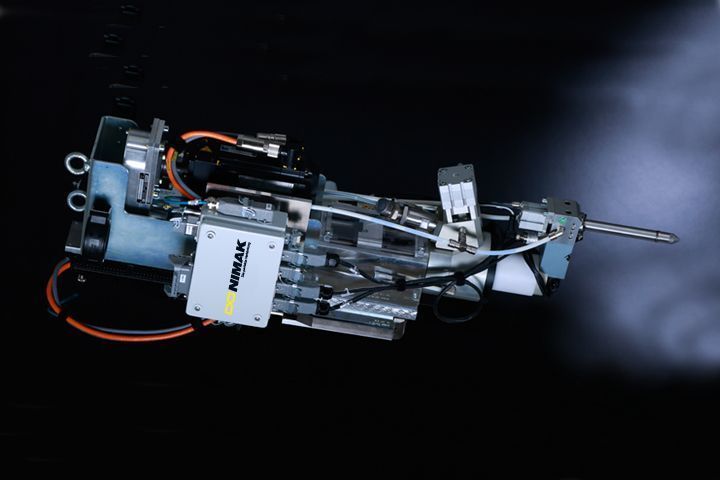

By the way: You can choose between operating the powerGUN on the combination controller we developed together with a renowned partner or - in conjunction with the innovative magneticDRIVE drive system – on a complete system with a customized master PLC for controlling all functions and robot interfaces.

High welding current and long duty times

The powerGUN can optionally be equipped with one or two high-power transformers for high welding current and long duty times.

Improved heat dissipation

An optimized water cooling system ensures improved heat dissipation.

Powerful execution

Great features of a strong robot gun: servo-driven drive, force sensor for force control, expanded cross-sections in the secondary area, version without gun compensation

Flexible deployment

The powerGUN can be optionally operated on a conventional welding controller, on the combination controller we developed together with a renowned partner or - in conjunction with the innovative magneticDRIVE drive system – on a complete system with a customized master PLC for controlling all functions and robot interfaces.

Typical applications

Technical specifications

Complementary products

We will gladly supply you with the control cabinet for the welding control including the related inverter together with your powerGUN. The programming is undertaken as per your requirements so that all functions such as the welding process, feed movement, force generation and compensation function are matched exactly to your demands. Furthermore, the cabinet has a ProfiNet interface to the robot.