With the a.tronNEXT dosing system, gluing robots work quickly and with high precision. That is because the dosing feeder, glue controller and drum pump - all the components are perfectly matched to ensure maximum performance Based on your individual requirements we will configure the automated dosing system so that it fits your concrete joining jobs. Regardless of whether adhesives, sealants or liquid insulating materials need to be processed - the a.tronNEXT systems accomplish that permanently quickly and precisely. That is because thanks to the specifically developed seals, a maintenance-optimized design and the use of standard components the a.tronNEXT dosing systems are exceptionally robust, durable, low-maintenance and highly reliable.

Gluing and dosing systems - now also available with integrated controller

Most gluing and dosing robots operate with a separate controller module. We now offer you the a.tronNEXT dosing system, in addition to the classic version, with an integrated controller in which the intelligence is mounted directly on the dosing feeder. In this design option, you can simply intervene in the controller on the system through a laptop, master computer or the panel. The advantages of such an integrated control solution are obvious: The plant needs less space overall, the investment costs sink by about 20 % and operation for the user is simpler. Furthermore, the dosing systems with integrated controller are ready to operate more quickly when starting production or after restarting because no indexing is required. Furthermore, the wiring expenditure, which is significantly less than with classic systems, also reduces assembly times and costs.

Only at NIMAK: Gluing and welding technology from one, single source

NIMAK is the only company in the world that provides innovative joining technology from the gluing and welding sectors from one, single source and together with first-class support in both technological areas. We take advantage of our decades of experience in resistance welding to open new perspectives with pioneering developments in the gluing technology sector. Our customers profit from optimized production processes through ideally matched plant components and uniform operating concepts. That is a win-win situation for everyone. And the a.tronNEXT perfectly adapts in the system environment when using gluing robots.

Completely automatic gluing stations with high-performance components

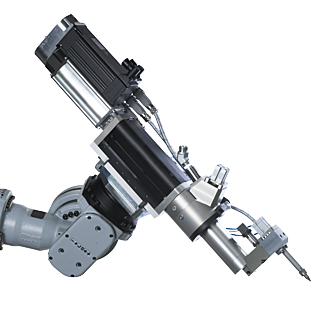

a.tronNEXT dosing unit

- Dosing volume for 1C glues: 20/60/150 ccm

Dosing volume for 2C glues: 60/100 ccm per component - Optimized material flow with the FIFO principle (First in – First out)

- Completely heated up to the application nozzle

- Servomotor driven, maintenance-free drive through permanently lubricated ball screw

- Modular design

- Replacement of all components without changing the TCP

- Nozzle shaft with integrated heating without interruption contour

- Fast-switching valves

- Integrated pressure sensor before the discharge valve

- Optional: fully-integrated optical seam monitor

a.tronNEXT gluing control

- Designed around Siemens build on S7-300 components

- Operation using 19‘‘ touchpanel

- Clear, user-friendly setup

- Precise application seam through perfectly matched pressure and feed control

- Analysis and logging of glue seams

- Updates and support can be carried out from a central location

- Optionally as compact cabinet or with separate cabinets for dosing feeder and pump control

a.tronNEXT drum pump

- Robust design based on industrially-manufactured standard components

- For 30 L-, 50 L- and 200 L drums

- Single or double drum pump

- Cold or fully heated

- High pump delivery rates for fast filling times

- Path measurement displays the exact filling volume in the drum

- Remnant volume-optimized follower plate

Benefits in an overview:

Very durable: the highest availability

The availability of the a.tronNEXT dosing systems is higher than 99 %. That means you can assume that your system will work precisely continuously and generally fault-free. The patented multiple sealing face, specially developed seals, a maintenance-optimized construction and the use of standard components ensure that.

Fast and precise: high reproducibility and

Perfectly matched components in the controller and dosing feeder along with extremely exact prepressure adaptation with pressure sensors in the application head ensure that a.tronNEXT dosing systems work with high precision over a long period of time. The perfect interaction of the PLC and fast-acting valves also guarantee high control speed.

Reduced downtimes: low maintenance expenditures, simple replacement of wearing parts

We have optimized all wearing parts like nozzles and seals so that they can remain in use for a very long time. That reduces repair and machine failure times. On top of that, the maintenance expenditures of the a.tronNEXT systems are very low. The required work can be accomplished in a very short time.

Global spare part delivery: simple handling

In the truest sense of the word, the a.tronNEXT dosing systems are constructed simply and are based on standardized, large-scale production elements from the SIEMENS Simatik series. With this strategy not only do we ensure the high quality of the plant, but even guarantee that spare parts can be obtained anywhere in the world in a short time.

Typical applications

Our automated a.tronNEXT dosing systems can be used both as standalone plants as well as in the frame of large production units. Our excellent performance is especially evident in large-scale manufacturing, for instance in these sectors:

- Car body engineering

- Power trains

- Hybrid joining processes

- Lightweight construction

- CFRP

- Material mix

Performance characteristics - a brief overview

| Application speed (in mm/s) | Up to 500 |

| Pressure range (in bar) | 4 - 350 |

| Cycle time of the soft PLC (in ms) | 2 |

| Delivery rate pump (in: l/min) | 1.5 |

| Valve switching time (in ms) | 11 |

| Application of | epoxy glues, polyurethane glues, silicon, highly-viscous material |

| Seam types | Buttonhole seam, lockstich seam, swirl, flatstream, wide slot |

Test like the professionals - with NIMAK glueTEST

Ensure the availability of your equipment at all times!

With the NIMAK inspection and test system for dosing / gluing equipment.

Optional fully automatic test sequence or individual test of all important components and functions

- test of valves and dosing chambers

- test of the drive

- test of the heating board

- test of the heaters

- test of the pressure sensor

with complete documentation of the maintenace history.

For systems repaired by the customer or for preventive maintenance – preventive detection of later system failures.

Valid for common SIEMENS and BECKHOFF based systems.

Developed together with practice for practice! Already successfully in use at BMW in Munich.