Whether galvanized steel sheet, high-strength steels, aluminum welding or gluing: NIMAK has the solution

Our customer's joining technology requirements are diverse: welding galvanized sheets,welding together steels of different compositions and strengths, reliably joining aluminum, finding and implementing solutions for the material mix. NIMAK is your competent partner for every case. After all, our wide range of products and services range from manual and robot welding guns and welding machines as well as innovative gluing and dosing technology through individual automation solutions.

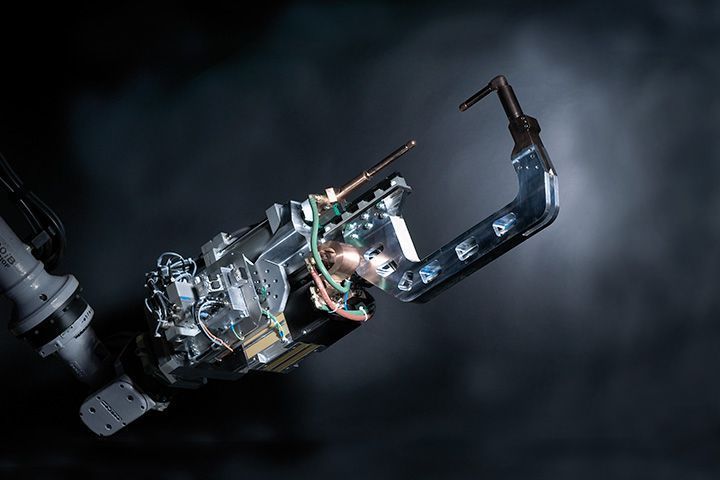

Joining sheets with the inventor of the robot welding gun

In the automobile industry and many other sectors, welding guns from NIMAK ensure reliable connections – when joining steels, aluminum and lightweight material through quality welding points. You can choose between robust manual welding guns for sporadic welding work at rework stations, in prototype construction or in CKD productions. And robot welding guns, which are also perfect for use in highly-dynamic robots and which help you achieve significant increases in productivity. Even though we primarily manufacture in series, every NIMAK welding gun is a unique specimen: specifically designed and constructed for your requirements. We are the only company in the world that has been released by all premium automotive industry manufacturers to meet customer-specific standards for welding guns. For our production that means: We have just the right welding gun for you, for sure.

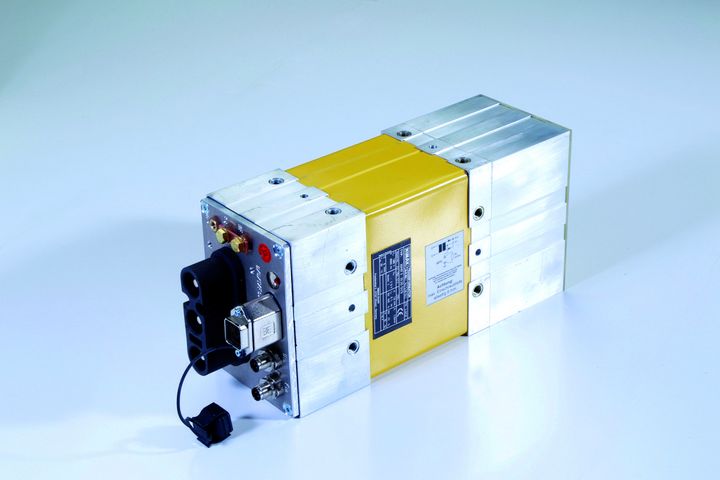

For spot and projection welding as well as for many other applications: our stationary welding machines

Based on our modular system, for you we construct stationary welding machines made for your particular requirements. And we manufacture the individual components ourselves - even the transformers. That guarantees that our machines continuously work reliably. And you profit from high-performance systems that meet the highest quality requirements. We develop and manufacture for you individually designed machines for spot, roller seam and projection welding; namely in various design variants - for instance as floor-mounted or table-top models and with various power levels. You can also obtain the required accessories and devices for the operation of the machine from us. NIMAK stands for tops quality and comprehensive service from one, single source.

Automation solutions for perfect connections

The ability to master joining challenges and devise systems for quickly and reliably automating production steps - those are our strengths. Based on your specific requirements we develop, design and manufacture for you high-performance systems such as robot welding cells, rotary indexing systems and linear transfer plants. Simultaneously as the only supplier in the world we provide welding and gluing technology from one, single source - gladly also as a combined solution within an automated plant. As soon as the individually manufactured systems are ready for your use, we put them into operation in your factory and train your employees onsite. For us, that belongs to full service.

Customer-focused solutions, innovative technologies

The automotive sector and many other industries are in the midst of a transformation: new, environmentally friendly, lightweight construction methods and the expanded use of plastics, carbon-sheet metal connections and aluminum have increased the requirements placed on modern joining technology. To make sure you are perfectly equipped for the changed production process requirements of the future, when using resistance welding we provide you with a range of welding processes that is unique in the sector: For the current injection, depending on requirements and customer request we rely on on alternating current, medium frequency or capacitor discharge technology or - brand-new: short-pulse welding. The required electrode force can be generated with servo-drives as well as with pneumatic systems or with our self-developed magneticDRIVE process. And that applies not only to the segments of welding plants and automatic solutions but to our robot welding guns as well.

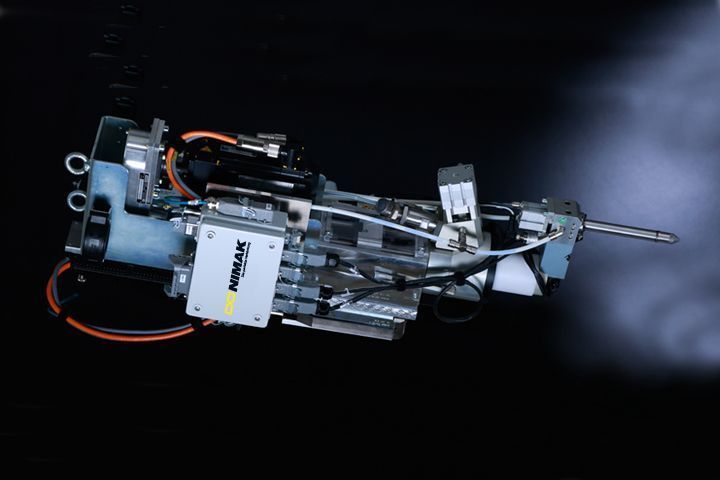

The latest gluing and dosing technology

In the environment of industrial production, adhesive connections are being used with increasing frequency. That applies to the automotive sector as well as other industries. That is because thanks to improved glues and new processes, modern gluing and dosing systems provide new opportunities especially with regard to the topic of lightweight construction. That is why we have used our many years of experience in the automotive area and the cooperative relations to premium branch manufacturers to develop a powerful complete system for automated gluing and dosing: the a.tron. It basically comprises the dosing feeder, a drum pump and a controller. We individually configure each one to match your requirements. If desired even with an integrated controller that sits right on the dosing feeder for simplified handling and reduced investment costs. High quality and extremely robust, the a.tron convinces in the production process through absolute reliability and precision. At the same time, it produces first-class dosing results with a minimum of maintenance expenditures.

Welding aluminum, high-strength steels or galvanized sheets, gluing or welding various materials in a material mix – NIMAK is your partner for the perfect connection.