You are confronted with a concrete welding job: do you want to connect materials with resistance welding and are you looking for a welding machine that meets your individual requirements without exceeding the budge frame? Then we have exactly what you need: our spot, projection and roller-seam welding machines, which we adapt to your individual requirements with our modular system. At the same time we work in accordance with our high NIMAK standard, complying with the valid machine directives or your individual standard – whichever you prefer. Supplementary to the plant itself, we fabricate and supply you with all the devices and accessories you need for operation - from feed devices for weld-on parts and welding fixtures up to welding control cabinets, coolant coolers and much more. In a nutshell: We have just the right machine for you and provide everything from one, single source.

Resistance welders in different versions

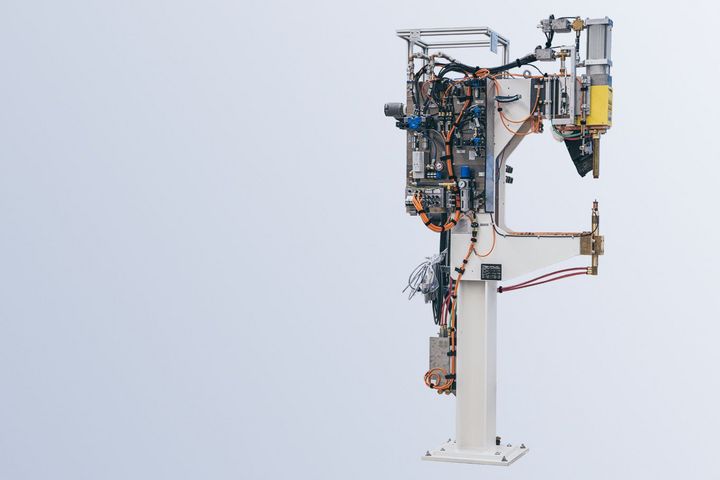

Depending on the power and application area, we build our welding machines for you as floor or table-top welding machines. For the drive, pneumatic cylinders and servomotor systems through magnetic linear actuators of all conventional technical standards are possible. Furthermore you can choose between alternating, medium frequency and capacitor discharge technology. The various types of our spot, projection and roller-seam welding machines differ in the nominal power, electrode force, electrode stroke and available welding window. Our experts will determine which variant best meets your requirements. Let’s talk about your concrete project - we would be glad to advise you and configure your individual welding machine for you.

In-house part fabrication for high-quality resistance welding machines.

Based on our welding machine standards and your requirements we will create your resistance welding machine based on modular technology including everything they entail. We manufacture the individual components predominantly ourselves. That way we can ensure that every single part meets the highest quality standards. The core component of each resistance welding machine is the transformer. We even manufacture the transformers in our own factory. And namely quite different types. Whether specifically developed special transformers or large-scale standardized transformers as per ISO standard - our transformer experts build everything in the demanded time and with absolute reliability.

Solutions from the NIMAK welding lab

To find out how the welding machine needs to be configured so that it exactly meets your requirements we first run trials on your samples in our own welding lab. We have a great number of various machines with different technologies available to accomplish that. After the main parameters have been defined we can weld the first pilot series for you and put it through the paces. Here we work with comprehensive professional equipment to create the finest microsections. That way our experienced technicians approach the solution to your welding problem step by step and develop the ideal machine for your requirements.

Resistance welding technology at the highest quality level

We have been manufacturing welding machines for over 50 years. The knowledge and experience we have collected during this time can be found in every one of our welding machines. Simultaneously we have our finger on the pulse of the times: we develop new, innovative drive processes such as the completely new and unique magneticDRIVE along with pioneering control technologies. We make sure that NIMAK resistance welding machines deliver first-class work long-term. During the design and manufacturing phases of the machines, trained skilled workers constantly run quality checks in the various production areas and document the findings. Right before delivery, every machine is once more put through a final inspection during which we check and log whether all relevant standards and values are maintained. Only after the device has cleared this hurdle do we deliver and install your resistance welding machine onsite. Since our machines are extremely rugged and durable, they also generally work reliably for a long time. But should problems happen to arise, just give us a call. Our experts for resistance welding will quickly be onsite and find a solution.