Every welding gun that we develop and fabricate is unique: specifically adapted to the demands of your production challenges and manufactured by us at the highest level of quality. We have been developing and expanding the expertise needed to accomplish that during many years. After all, we are the inventor of the robot welding gun and worldwide the sole provider that has been released by all premium automobile industry manufacturers to meet customer-specific standards for welding guns. We manufacture the required components predominantly ourselves. That is how from the development and design through fabrication we ensure that every welding gun you receive from us meets the high demands placed on quality, productivity and reliability that you rightly insist on while guaranteeing that we can react quickly and flexibly to possible short-term changes.

A spot welding gun that fits your requirements

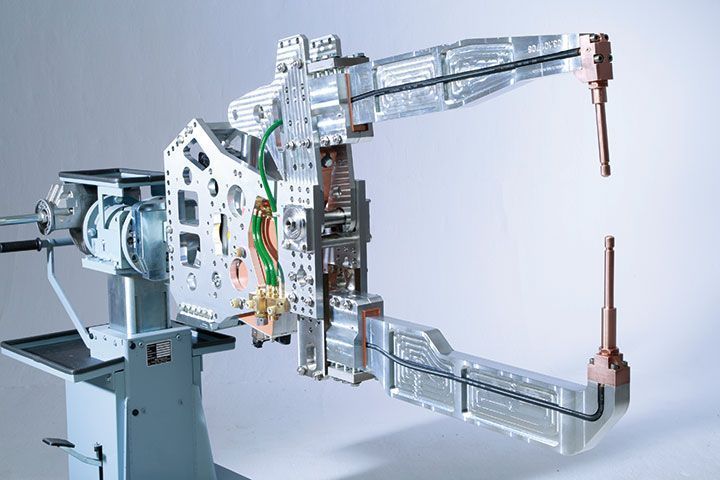

As a premium automobile manufacturer you have your own standards for your robot welding guns and as an automotive supplier you look for welding guns that can be put into service quickly, as an industrial company you need customized solutions for concrete requirements within your automated production processes - we can certainly find the perfect spot welding gun for you for any situation. Because, we are not merely familiar with the standards of the automobile industry, but also use a vast expertise and experience to develop welding guns for you. With the multiframeGUN we are also offering you a modular system we can use to quickly and cost-effectively design the robot welding guns based on just a few components and on top of that the guns are matched to your concerns. Let’s talk about the welding challenges you face - we have just the right spot welding gun for you.

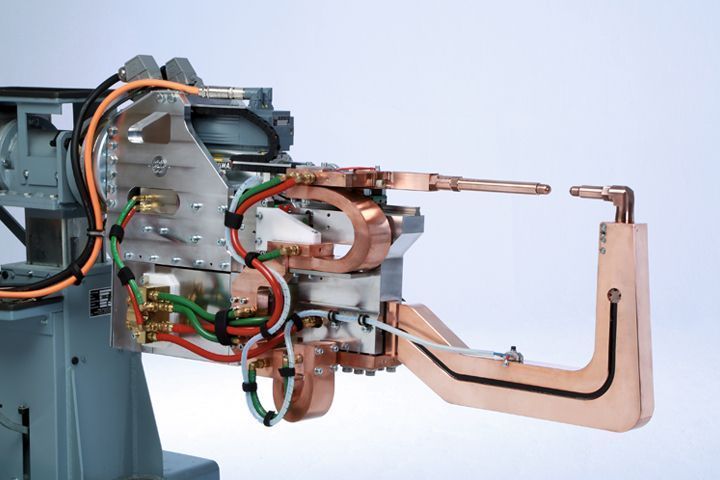

For usage in the multi-material mix: the aluminum spot welding gun

At the moment, hardly any sector is undergoing as much change as the automotive industry. Innovative drive technologies and the use of new materials put high demands on production and thus also on the spot welding guns being used there. We support our customers in actively designing this process of transformation and have developed our own aluminum spot welding gun: the powerGUN. It supplies high welding currents and ensures the required cooling, which facilitates fast, process-reliable aluminum welds. An innovation that our makes our customers successful and makes us proud. To once again confirm this gun which is specifically aimed at the material aluminum: We are one of the highest-performance welding gun manufacturers in the world.

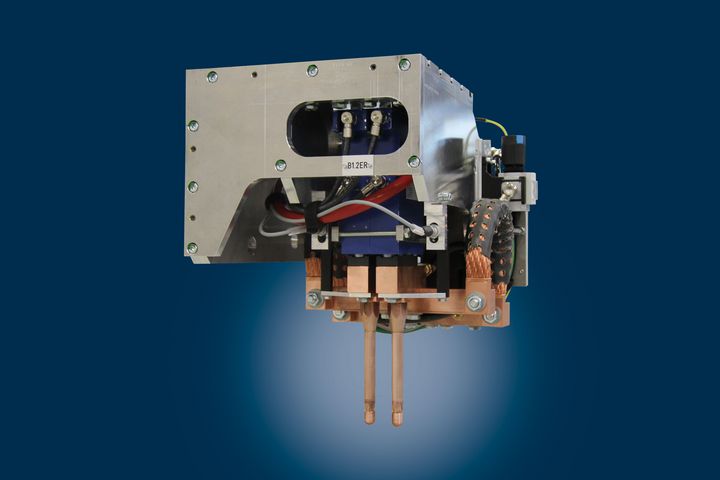

Just right for spot welding guns: innovative controllers

From the servo-controller topCONTROL for activating and controlling the servomotor up to complete combination controllers for the powerGUN which connects a welding controller with adaptive control with a high-performance servomotor controller – our controllers make your spot welding gun intelligent. As the servomotor controller, topCONTROL is also perfect if you want to prepare existing plants for the welding challenges of the future. The motto is, supplement the controller for spot guns instead of replacing or retrofitting expensive older-generation robots. Not only does that guarantee the maximum functionality: from the points of view of costs, ecology and sustainability this approach is often the method of choice. Please feel free to get in touch with us if you want to renew or enhance your system. We will support you in your efforts to find the best solution and will professionally implement if for you.

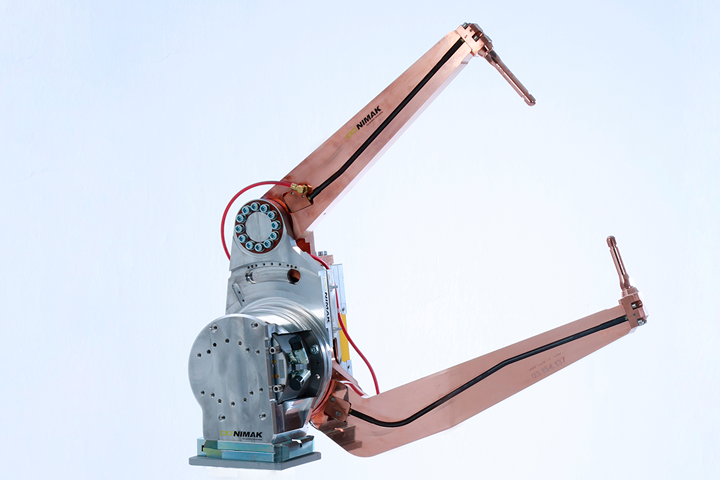

For even more power: magneticDRIVE

Whenever the point is welding aluminum and high-strength steels or combinations of different materials, special demands are put on the electrode force and the follow-up characteristics. Conventional drive systems such as servomotors or pneumatic cylinders are often pushed to their limits here. That is why we continued to do research and for our demanding customers developed a world’s first: the magneticDRIVE. This drive uses the extremely variable force and above all the immense speed and dynamism of modern, microprocessor-controlled electromagnets and takes advantage of them for resistance welding. Thanks to force-constant control, lightning-fast implemented force profiles and perfect follow-up characteristics, you can open the way to new regions of resistance welding with the magneticDRIVE. We would like to warmly invite you: Delve into the details of something completely new and unique, the magneticDRIVE: