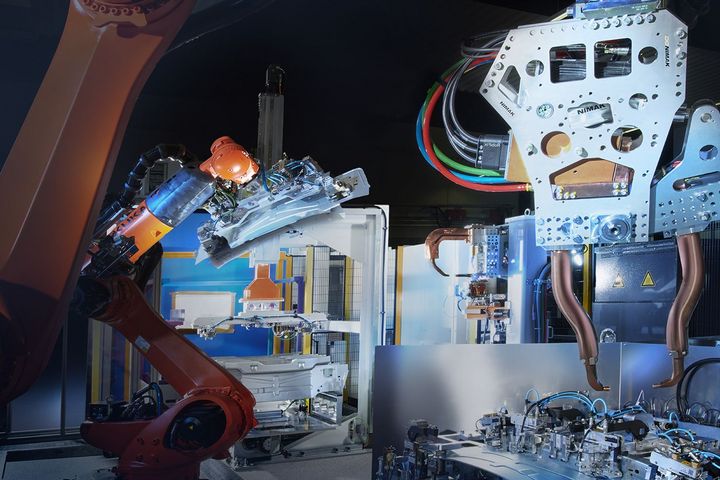

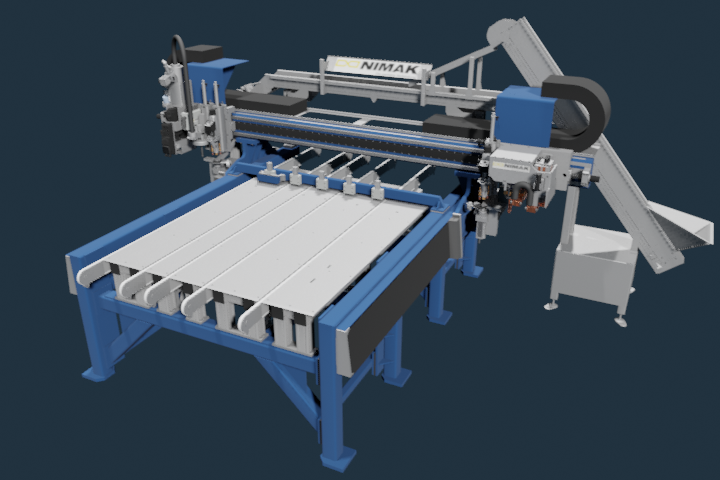

With expertise, experience and great innovative ability for you we develop solutions for industrial automation in the sector of welding and gluing technology so that you can achieve your goals: more efficient production processes, ultra-precise connections and tangible productivity increases. At the same time, we will gladly put the full extent of our wide range of services to work for you. We master all processes of resistance welding, use innovative drive technologies with which you can obtain outstanding results when processing different materials, and provide you with high-performance gluing systems. To master these technologies is one thing. But the real art of engineering is to use this basis to develop individual automation solutions that are exactly matched to your concrete requirement. And that is exactly what our team puts perfectly into practice every single day. We develop and fabricate innovative solutions, for instance robot welding cells, rotary indexing systems and linear-transfer plants for you from one, single source.

Ground-breaking total concept for industry: Automation and first-class service

We support you in successfully mastering industrial joining challenges through automation. To accomplish that, the NIMAK development and design team goes to the plate for you: designing, drafting 3D models, testing and manufacturing high-performance plants. During the entire process we stay in close contact with your experts in order to guarantee and fully take into consideration your ideas, requirements and plans. Before the finished plant is delivered, we once again put the plant through the paces before our fitters put it into service onsite on your premises. You can count on our support here, too. We would be glad to instruct your employees, run training courses and take care of the maintenance work for you. In a nutshell: We are your permanently reliable partner for industry and automation.

Full service - from the project planning to the complete assembly plant

The use of automated assembly plants simply makes your production processes more efficient and contributes to higher quality and productivity. To be able to optimally achieve these aspects, we offer you full service to cover everything concerning the development and operation of automated assembly plants. How do we do that? Basically, in these five steps:

1. Definition of welding parameters

Just show us the workpiece involved. We will evaluate the design from the welding technology perspective and make optimization suggestions with the goal of making your production processes as simple and efficient as possible. After that things move on into the welding lab where we will perform trials on your samples, create prototypes and test them. At the end of this development step the welding parameters are stipulated. The basis for your new plant has been created: the planning can start.

2. Process planning

The next job is to take the technical performance and the newly planned automation system into consideration: What welding power is necessary? How high should the production quantity be? How exact are the onsite circumstances? That is also the moment when we consider if we can use technology from our standard program for the development of your plant, which we will adapt or supplement for your issues. That is interesting from both the technical and the economic points of view.

3. Development and design

On a computer, our experts will create 3D/CAD models of your new plant and work closely together with the specialized colleagues from the development, research and electrical department. And that is very simple, because at NIMAK development and design are all taken care of under one roof. Before creating the detailed construction drawing, all relevant functions of your automated production can be already virtually checked.

5. Installation and initial start-up

Our technicians and the experts from our international partner network will install your plant for you onsite - in Germany and anywhere in the world. At the same time they will make sure that all the connections fit as planned, install the robot technology, feeding technology and electronic and welding components. They will start-up the machines for industrial automation, run functional checks and test runs and train your employees in the factory.