Modern gluing technology and dosing technology is experiencing enormous growth rates in automobile engineering along with many other sectors No wonder: Precisely for new, environmentally friendly lightweight construction with plastics and carbon-sheet metal connections, this joining process provides completely new possibilities. With the a.tronNEXT dosing systems we support companies all over the world in successfully taking advantage of the consequential opportunities. Our automated gluing and dosing basically comprise three components: the a.tronNEXT dosing feeder, the a.tronNEXT glue control and the a.tronNEXT drum pump. We individually configure the dosing system, which is tailored to your requirements, based on these components. So that you can successfully master the most demanding joining challenges. What all a.tronNEXT plants have in common is that they are manufactured to be extremely robust, low maintenance and very durable. To ensure that, we developed special seals and rely on the use of proven standard components. You profit from the result with permanently reliably-operating and highly precise gluing systems that, in the frame of your production process, reliably perform first-class joining work with a minimum of maintenance expenditure. By the way: You can use your a.tronNEXT just as well as both a 1K and a 2K dosing plant. Other glues such as sealants and insulating materials can also be easily processed with our gluing and dosing technology units.

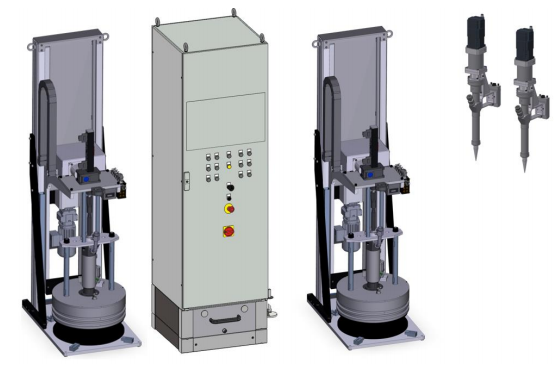

Innovative gluing technology: only one control cabinet for doser and drum pump

The experience of many decades of development work has taught us: Anything that is good can still be made better. That naturally also applies to the gluing technology sector. That is why we have developed a system which integrates the control for doser and drum pump in only one control cabinet.That reduces the space requirement as well as installation efforts, lowers costs and makes handling even easier during the production process. Thanks to the universal control, the system is immediately ready for production because a referencing of the doser is not necessary when rebooting the system. The way we see it, many good reasons to decide in favor of the new type of a.tronNEXT. That’s why we would like to invite you to have a talk with us about this innovative topic of gluing technology.

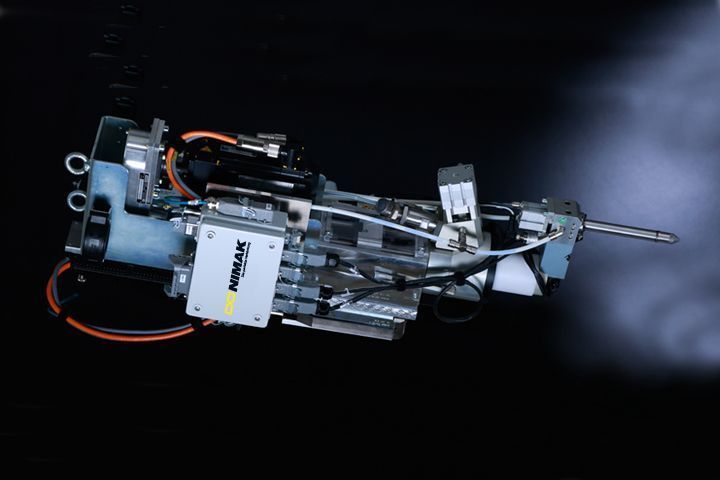

From the dispensing valve to the controller - perfectly matched components for durable plants

You put high demands on on the gluing systems that are used in your production. With the a.tronNEXT gluing and dosing systems we offer you high-performance plants with availabilities of over 99 %. To achieve this high value, from the dispensing valve and seals through the controller we rely exclusively on parts and components that meet the highest quality demands. Perfectly matched, they ensure that a.tronNEXT plants work precisely for a long time.

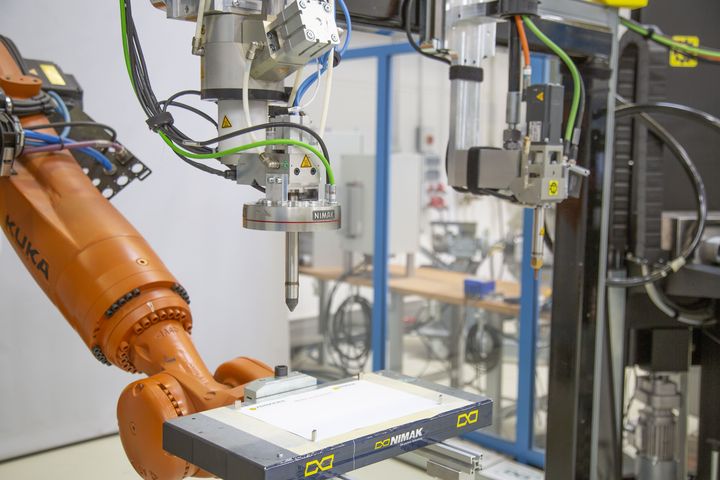

Automated gluing technology or manual gluing plant - we can offer both

Along with the automated dosing systems of the a.tronNEXT series, for you we also have a manual gluing plant in our line. After all, there are always gluing jobs that require manual work. With the NIMAK manual gluing plant, that is accomplished with ease and precision. It is easy to use, absolutely robust and helps with very precise glue application, even manually.

Welding and gluing technology from one, single source

NIMAK is currently the only manufacturer in the world that provides you with the welding and gluing technology for both joining processes from one, single source. Including service and everything else that is entailed. We have used our experience from the welding gun and machine sector to develop innovative gluing systems. So we can justifiably and proudly claim: Regardless of which joining challenge you are facing, we have just the right gluing and dosing technology for you.